(originally published by Weaver Industries, Inc.)

There are literally hundreds of different graphite grades in the world. The only graphite and carbon we work with are the man-made, or synthetic, graphites. There is mined graphite as well, but we never machine that material because of the hazards associated with it, and quite honestly, the synthetic graphite has more uniform properties. Weaver Industries, Inc. purchases our graphite from all of the various graphite manufacturers.

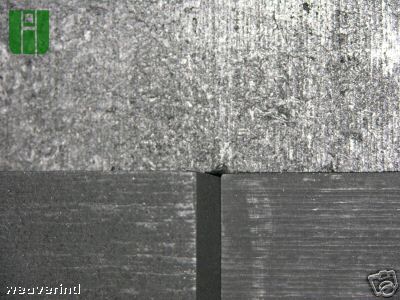

To give you a rough understanding of terminology that I use when describing graphite grades, the picture above shows three different grades: Electrode (Steel Mill Electrodes not EDM) Stock, Medium Grain and Fine Grain Graphite. It's extremely difficult to break the grades into small groups, and it all becomes more confusing when you look at the various people selling graphite, either on EBay or other places. Then you have grades that may be very similar but are labeled different depending on EDM use or other work.

* Electrode Stock - The Steel mill electrode material is a very course grain (up to .250" grain size). You can actually see the grain in the material. In between the grains you will find small holes or gaps, not that you will find 1/4" holes, but you certainly will find porosity that will show up on your glass. Each manufacturer has their own designations for the grades in this category. It is a great material for thermal shock, after all, these electrodes are used to run thousands of volts of electricity through the graphite in the Electric Arc furnaces to melt steel. Basically, if you need a good insulating graphite slab that you won't be using to obtain a good finish on the glass, you could purchase electrode grade. Here's a thought, instead of using a good fine grain graphite as a work table, purchase a block of electrode grade graphite to provide you with insulating properties, and then simply attach a thinner fine grade plate onto your work surface that could be replaced at a lot less cost.

* Medium Grain - This is kind of a general, all-purpose graphite, that has a typical grain size running in the .030" to .060" grain size. Once again, this material has all of the excellent properties of graphite, but is a little more porous than the fine grain materials. But then again, it should sell for typically half the price of a fine grain material. Here's where a lot of difficulties come in: you could find grades from CS, HLM, 873S, CBY, HLM50, to hundreds of other grades that fit this category, all with different strengths and weaknesses. They are great as crucibles, precious metals molds, glass molds and tools, etc. Because the grain is larger than the fine grains, you could find some difficulty with obtaining very fine finishes. Not only do you have to deal with all of the grades, you also need to think about, or worry about, what size the starting material was. You will find small size blocks of HLM or CS that have certain properties, but then if you choose the same grade and it came from a very large size block, say 24" x 48" x 72", it will have different properties. You could also see grades like PGX that is typically a very large diameter material, 50 inch and bigger, that have larger grain sizes. Even through this difficulty, you will find this graphite category very practical for many of your applications.

* Fine Grain - This is the hot topic for glass. As I said earlier, you could expect to pay at least twice the price for these materials than for the medium grains. In this category you will find materials that have a grain size varying from .0004" up to .002" size. Once again, there are hundreds of grades in this category with specific uses for each one, each having their own specific properties, strengths and weaknesses. Some are designed for EDM electrodes, bearing/seals, hot pressing, molds, substrates for SIC coatings, rocket nozzles, and thousands of other applications. Typical grades that I lump into this category would be ATJ, 2191, EK90, and a whole host of other grades. As I stated earlier, it's absolutely impossible to lump graphite into small groups like I did, each one was designed by the manufacturer with their own secret recipe to obtain the properties for the applications for which it was designed. The grades I don't lump into this category are many of the Poco Graphite grades. If I list Poco grades like DFP1, DFP3, etc., I would call them out as Ultra Fine Graphites. There is no doubt Poco makes a great dense material, and if you want those properties, you will pay for them.

Items that I didn't cover are still hundreds; there are carbon grades as well. Carbon is the step before performing the graphitization. These grades are hard; not necessarily finer, because a lot of the grades are densified after becoming carbon and before they graphitize them. Carbon is typically very hard to machine. Carbide tooling is a must, and you are better off going right to diamond to do the cutting. Let's muddy the water some more; there are grades like JP1300 from Carbone that is a Graphite/Carbon. It is a very fine grain material with some of the properties of graphite, and some of carbon. You can obtain super high finishes with the material, and it is so hard that it should perform very well, but it is very hard to machine.

Bottom line, if you ever have questions about what some of the differences are, or what someone is trying to sell you, ask them the grade, research the grade and ask questions. I don't know everything about graphite, but we certainly have been machining a lot of it for a lot of years. Side note, if you never machined the stuff and are planning on doing so, here are some helpful hints: Graphite dust gets into everything and goes into everything. You should plan on spending a lot of money just in maintaining equipment and purchasing new machinery. It will get into your gearing, and the ways of the machine. Even though they sell graphite powder as a lubricant, when it gets into your machine (and it will), it will prematurely wear your machine out very quickly. The other thing to consider: graphite is electrically conductive, so you can imagine what graphite dust will do inside an electric motor or CNC control cabinet. Better still, get us to do all of the graphite machining for you.

Other side note, change your shoes before going back into your house, or you will see black foot steps everywhere, and everything turns a nice shade of grey. Ha Ha, industry joke.

I hope this helps.